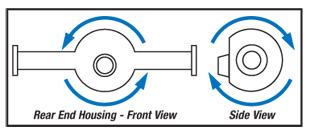

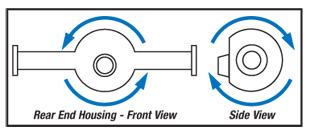

Back in 1687 Sir Isaac Newton published his Three Laws of Motion. Newton’s Third Law, which essentially says, “For every action there is an equal and opposite reaction,” certainly comes to bear in terms of rear end housing dynamics. We know that when a car launches off the starting line the rear end housing will want to rotate opposite of the direction of the tires. Race car chassis builders, of course, endeavor to harness this tremendous force by means of 4-link rear suspensions and other traction systems.

But there’s also another dynamic at play here; the torque of the engine exerts a twisting force on the chassis and rear end that is opposite of crankshaft rotation. Depending on the engine torque at launch RPM, torque converter multiplication (automatic transmissions only), transmission first gear ratio and rear end ratio many cars will exert 10,000-plus foot pounds of torque. Engine mounts transfer the bulk of this twisting force to the frame, with the suspensions affected accordingly. You’ve no doubt seen cars launch wheels-up with the left wheel higher. Bingo! What’s more, this “twisting” force is not limited to the front end. It transcends all the way to the rear end. In the piston-driven aircraft world this is known as “P Factor” and requires pilots to apply control pressure to maintain a wings-level climb.

So, how do you counteract this torque? A proven solution is to utilize an anti-roll assembly that can be adjusted to apply force to the rear end housing as required to counteract body roll. Racers and car builders agree that employing an anti-roll bar produces quicker and more consistent 60-foot times in most applications!

Mark Williams Enterprises offers two styles of anti-roll assemblies that have been embraced by many leading chassis builders. The basic unit (p/n 35100) that works excellently in the majority of doorslammer applications features a 1-1/4" o.d. chromoly tube that is serrated, with splined 7075 aluminum outer arms that can be adjusted. This is preferred to through-bolt designs where the hole can become oblong. The bar is mounted to the chassis by means of special brackets that have a 1-1/4" i.d. spherical bearing (p/n 35103). A linkage kit (p/n 35110) is used to connect to the rear end housing.

For higher horsepower applications where additional stiffness is required, M-W manufactures an anti-roll assembly that features a big 3" tube (p/n 35250). These can be made to any width required of the installation. Special spherical self-aligning aluminum/Delrin® mounting blocks are employed.

Consistent launches and straight-tracking are important factors in winning races. Equipping a race car with an anti-roll assembly is a key step in that direction.

|