Toll Free: 1-866-508-6394

OR Contact Us

OR Contact Us

Shop by Category

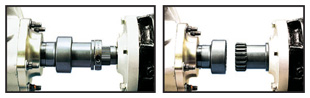

| While driveshafts provide the critical link between the engine/transmission and rear end in most vehicles with suspensions, dragsters, etc. with solid-mounted rear ends will rely on couplers. Obviously there are similarities in function, but there are also ways that standard coupler and yoke designs have been improved upon to make things easier for racers and also provide superior service life. Probably the weakest link in any 1350- series driveshaft is the U-bolt that secures the universal joint to the yoke. To prevent the universal joint from rocking out of the differential companion flange, Mark Williams Enterprises developed a billet steel “cap” that provides significantly more contact area and holds the Ujoint securely in place.  “Rapid Release” yokes allow the driveshaft to be disconnected at the transmission, saving time. There’s a lot to look for in transmission yokes. Many transmission manufacturers are pushing tailhousings equipped with needle bearings and these require special yokes that have been heat treated for extra hardness and have the correct diameter (which typically varies from the bushed housings of the same manufacture). Standard M-W transmission yokes are CNC machined from 4340 steel forgings and re-heat treated to over 200,000 PSI. They are 100% machined to remove any surface irregularities and have a special O-ring plug seal to prevent fluid seepage. A series of unique “Rapid Release” transmission yokes feature removable steel caps that allow the driveshaft to be disconnected at the tranny, rather than at the pinion, to facilitate fast at-track transmission swaps. This same dedication to between-rounds efficiency carries through to M-W's coupler lineup as the firm has developed a series of Quick Disconnect Powerglide Couplers that feature a 2-piece unit that can be slid back  “Quick Disconnect” PG coupler facilitates quick and easy transmission removal at the track. M-W's couplers are made from 4140 alloy steel and hardened using the special Austempering process. They are extremely strong, yet have excellent ductility. If the distance between the transmision and rear end is too great for using couplers alone, solid 4340 shafts are available to accommodate 16, 32 and 35- spline setups. A one-piece shaft can be custommade to any length up to 34 inches, while the more popular multi-piece driveshaft (includes two couplers and two collars) can be shortened up to 2" on each end to facilitate removal of the shaft. Taking advantage of these special couplers and yokes can give racers a meaningful trackside advantage, particularly if deep in eliminations. Being able to quickly change transmissions or converters has won events for many a racer. |

|